How Associated Food Stores is

Modernizing the Future of Grocery Wholesale

A key selling point of the software was its ability to connect routing and payroll, bringing two previously disconnected systems into one platform

— Justin Johnson, VP of Transportation and Warehousing at AFS

Instead of having our workload spread across nine batches, we moved to three evenly distributed order times. That alone significantly increased efficiency across warehouse operations and transportation,

— Justin Johnson, VP of Transportation and Warehousing at AFS

Quick Fact

1940

Founded

Nearly 500

Stores Served

Utah, USA

Headquarters

Before

9 Order-In Times

Multiple Driver Check-ins

Fragmented Systems

After

3 Consolidated Times

Just 3 Check-ins Max

Unified Kaleris Platform

Associated Food Stores (AFS), a co-op grocery wholesaler serving nearly 500 independent grocers, faced logistical challenges rooted in outdated ordering and routing systems. Each member store relies on AFS not only for delivery and distribution but also for its long-term success. Finding a solution that streamlined processes while honoring the traditions of AFS' ownership model was critical to optimize daily operations and prepare for future growth.

Simplifying Legacy Systems and Operational Inefficiencies

By 2018, AFS had grown increasingly constrained by the fulfillment process. The organization coordinated nine separate order batches throughout the day, requiring warehouse, dispatch, and transportation teams to manage disconnected workflows. This system created inefficiencies across the business, from an uneven workload distribution for warehouse staff to drivers managing complex schedules and routes.

The growing fleet of trucks required to accommodate these inefficiencies drove up fuel costs, placing additional strain on internal teams.

The co-op’s ownership model added another layer of complexity. Because each store is both customer and part-owner of AFS, there was natural hesitation around changes that could disrupt long-standing workflows. Addressing these challenges required a strategic approach that clearly communicated the value to all stakeholders.

A Strategic Shift to Smarter Systems

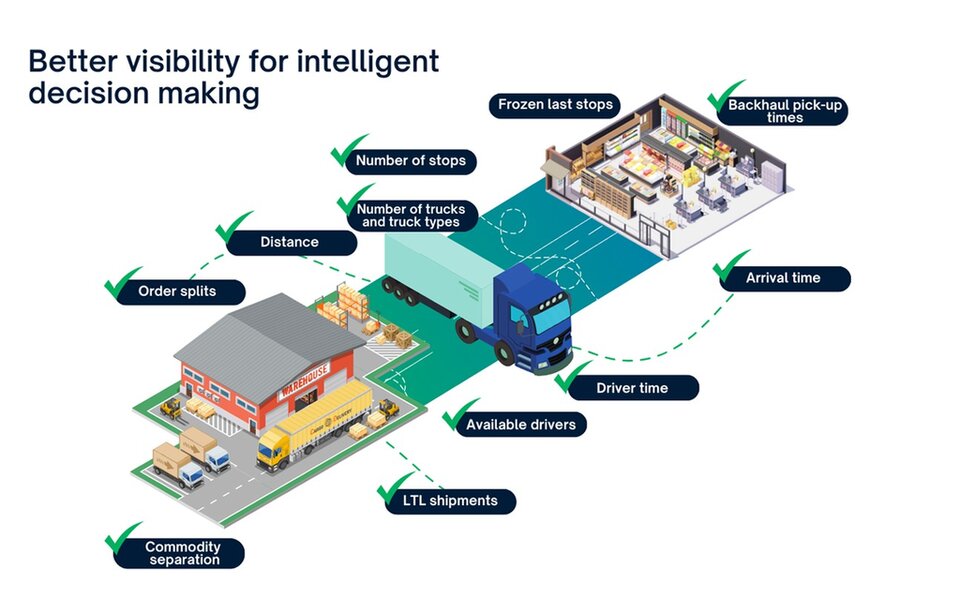

In 2018, AFS adopted Kaleris TMS (formerly CAMS Prospero) a comprehensive Transportation Management System that manages dispatch, driver payroll and routing.

A pivotal step in the transition was a data-driven case study conducted by Kaleris, a leading provider of supply chain execution and visibility software. By analyzing trends across grocery wholesale customers and other industries, the team identified inefficiencies in AFS’s nine daily order-in times and presented actionable recommendations. The findings showed that consolidating the nine batches into three would significantly boost operational efficiency and align AFS with industry standards. With these insights, reducing the number of order batches by 66% became a clear priority.

Rolling Out Change

Equipped with industry benchmarks and internal analysis, Justin Johnson and Glen Keysaw, Executive Vice President of Value Chain at AFS, presented the new approach to AFS executives, the Board of Directors, and ultimately, each store owner. The case was clear: streamlining order batches would drive measurable gains in productivity, scheduling, and delivery reliability.

Though the transition required buy-in from long-standing member stores, the results quickly validated the change. Transportation scheduling became more manageable, dispatch teams experienced less strain, and fewer trucks were needed on the road. The intuitive design of the Kaleris TMS made it easy for AFS employees at all levels to adopt the new system quickly.

Driving Impact Across the Business

The Road to Continued Innovation

The improvements following the implementation of Kaleris TMS showcase its transformative impact on AFS’s day-to-day operations. Kaleris TMS

Cut order-in times from 9 to 3, boosting efficiency and evenly distributing workload.

Balanced workload across batches by 30–35%, simplifying scheduling and labor planning.

Reduced driver check-ins from 9 to 3, enhancing day-to-day workflow.

Unified routing, dispatch, and payroll into one platform, improving visibility and coordination.

Optimized driver pay contracts with Kaleris, allowing smoother updates and better financial forecasting.

“My supervisors have Kaleris on speed dial. They always pick up,” said Johnson. “When I look for new software partners, I use our relationship with Kaleris as the barometer. No one else measures up. Every time there’s an update, we provide feedback — and Kaleris acts on it. That level of partnership is rare in the software world,” Johnson emphasized.

Looking ahead, AFS hopes to transition from three order-in times to just one. By leveraging Kaleris’ advanced route optimization capabilities, the organization aims to open wider delivery windows, improve routing efficiency, and reduce transit costs even further.

Beyond routing, AFS is implementing denser, cube-optimized pallet-building strategies to maximize trailer utilization while reducing transportation demands. As part of its long-term commitment to continuous improvement and innovation, AFS will continue to leverage advanced software tools to support operational excellence.

AFS’s partnership with Kaleris highlights the power of combining innovative technology with true collaboration. Through Kaleris TMS, AFS has established a strong foundation for scalable growth across its cooperative network.