To Stop Retail Losses Don’t “Prevent” Them, Understand them

Shrink is always an inventory problem stemming from a lack of data. However, it is not your only source of loss. It may not even be your biggest source of loss.

Shelf-app price mismatches or coupons that aren’t scanning and products arriving damaged, past expiry dates, or kept outside of acceptable cold chain temperature ranges – these are just a few examples of what may cause losses, and they’re happening at a much greater rate than one might think. The good news is that all of this is preventable. All you need is data.

When items start disappearing from retail stores, warehouse shelves, trailers, etc. or you just can’t seem to balance the books, you need to study the actions taken by the people who work for you, buy from you, or sell or deliver to you. To prevent losses, you need to have a way of detecting and documenting losses in real time or near-real time. You can intervene to stop a loss as soon as you know when, where, how, and why you need to act. That’s why “loss detection” efforts are going to work better than traditional “loss prevention” programs.

But to detect and then prevent losses you need to know:

- What is going missing and why?

- How are items disappearing?

- Where are items disappearing?

- What else, beyond theft, is causing inventory distortion?

- How do financial losses occur even when the shelf stock matches the inventory system?

A good loss prevention system is built upon a loss detection program of four C’s: create, capture, consume, and capitalize.

There are lots of different ways to detect losses and pinpoint the root cause of the loss. I won’t be able to tell you which ones are best for you without sitting down and talking to you about your operations, your facilities, your digital footprint, and more. However, leaning into the first three Cs of the “four C” strategy is imperative whether you’re trying to reduce losses within your retail store, warehouse, or distribution center.

- Create a way to track inventory movements and transactions and correlate people to those points in time inside and outside your four walls.

- Set up systems to constantly capture data about inventory movements and transactions.

- Have a way to consume all those data points in an aggregate manner and correlate them with people and places to create a record that details “what happened,” “when and where it happened,” and “who was involved.” This makes it easier to investigate why something happened so you can consider what you should do about it.

How to Detect Losses

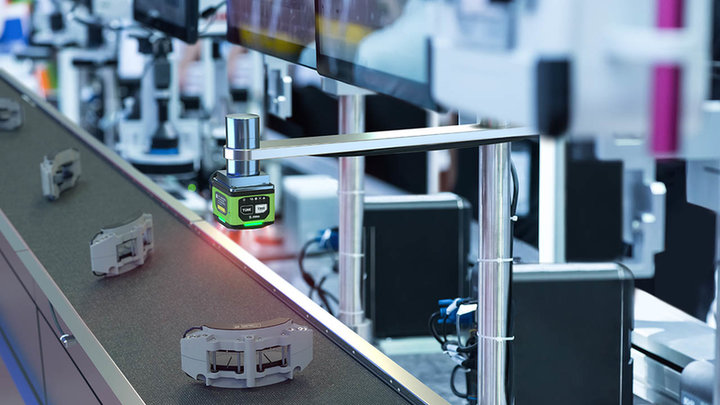

The best way to capture loss-related data is going to be with RFID technology. That’s because loss is an inventory problem, and there is no technology as effective as RFID at tracking inventory or equipment movements in real time.

If we look at what the market is doing, we will quickly discover that many companies are relying on RFID to stop a variety of losses: UPS, Walmart, and many more.

If you’re a manufacturer or retailer who wants to reduce your losses, you can use RFID to confirm which items were actually received from a supplier (versus what the supplier said they shipped or a dock worker said they handled). RFID provides visibility into what items are still in the building, where they are in the building, which items have left the building, how those items left the building, and whether those items were cleared to leave the building (i.e., paid for or approved for forward distribution).

In your warehouses and distribution centers, you can use RFID to confirm what you’ve received for forward distribution to stores or for temporary storage, confirm when items were packed, when they were shipped, and even when they were returned and automatically document each movement.

Some items won’t warrant an RFID tag right now, such as groceries, so you’ll need to track the movement of those goods in a different way. A barcode scan is an option, considering every good sold today needs a barcode affixed to it somehow to process the transaction, especially via self-checkout and other self-serve POS methods. However, if someone bypasses the POS or they think they scanned an item and they didn’t, you have no way of knowing that happened until the person and item are long gone.

That’s why it’s better to consider adding a vision technology so you can still track the movement of barcoded items that are not scanned.

Vision technology can “see” and actively record when someone walks out without paying for something quite well. It can also work hand-in-hand with other technologies – like gates and alarms – to both report losses and help on an action for intervention.

A combination of mobile computers or wearables with inventory management software can help to report on damaged or misplaced products.

The ability to connect with and update the inventory system in real time is key, no matter which hardware you use to capture and record transactions or inventory movements. You must be able to ingest data from multiple edge devices – cameras, RFID readers, barcode scanners, wearables, mobile computers, POS registers, and more – and connect the dots between all the data points captured at a moment in time.

Once you have the data at hand and we know what you’re dealing with, then you are ready for the fourth “C”: Capitalizing on these insights.

Unfortunately, there is no blanket “best practice” to apply here because some losses can be mitigated with process changes (and technology-powered control points) while others would require human intervention that could present personal safety concerns.

For example, when you have shoplifters who are smart enough to stay under the felony threshold with their thefts, or you have violent criminals causing problems, the only way you can stop them is to document and prove through transaction, RFID and camera records that show the crime, and repeated crimes, in an indisputable manner.

Loss prevention should not be working against the fundamental premise of retail, which is a frictionless, convenient shopping experience. Creating choke points or acting on assumptions versus facts will deter your best shoppers, leading to sales losses that exceed other forms of shrink.

The focus should be on loss detection so that equipment and supplies are restocked promptly. Environmental sensors, RFID, machine vision, computer vision, and other technologies that can track inventory movement and monitor current location and conditions, help you detect when there’s an anomaly in a product or shipment. If something is sitting outside at the receiving dock too long, you need to be able to detect that in real time as well. That’s how you prevent the loss.

About Zebra Technologies

At Ipsos Channel Performance, we partner with our clients to understand their shoppers and how they shop. We measure the execution of brand promises. We drive compliance and sales conversion. We improve performance across all sales and service channels – physical, contact center, and digital – and help deliver profitable growth. Learn more.

To learn more

Contact: Silvana Daehn

Email: silvana.daehn@ipsos.com.