FUSIONFRAME® system from KPS Global combines polyurethane foam and a structural core to optimize R-values and condensation resistance for walk-in cooler and freezer units

Walk-in coolers and freezers are in a battle against physics; it is a war to keep out the warmer exterior air and humidity. KPS Global has worked diligently to optimize the design and performance of walk-in frames and rails. This case study will illustrate how FUSIONFRAME®, an innovative frame system from KPS Global® can replace traditional wood structural framing on walk-in coolers and freezers. FUSIONFRAME delivers optimal structural and thermal-envelope performance, lower energy usage/ utility costs, a reduced carbon footprint and offers scalability for use with any size or configuration of walk-in cold-storage-unit solution.

The traditional frame choice, wood, is structurally sound, readily available, inexpensive and able to withstand the repeated opening and closing (and slamming) of doors. The downfall of a wood frame? It does not resist energy flow very well; this is critical since the walk-in unit must continuously fight to keep warm exterior air and humidity from intruding and compromising the unit’s structural and thermal operational capabilities.

FUSIONFRAME® provides the best of both worlds for grocery stores, restaurants, convenience stores, big-box retailers and warehousing operations by combining the structural benefits of wood with the insulative properties of foam. Store owners, operators and building designers will no longer have to compromise performance for cost again when it comes to walk-in coolers and freezers.

- Mike Eakins, Chief Executive Officer, KPS Global

The Challenge

The Solution

Heat can enter the walk-in unit in a variety of ways, from open doors to room-temperature product stored in the unit, and from lights, motors and humans. Vapor can work its way into the walk-in unit’s framing system and collect on its wood surfaces. If the wood framing becomes saturated with moisture, its R-Value will degrade over time. When the R-Value is reduced, the temperature of the framing is also lowered, which can lead to the formation of ice within freezer panel joints or condensation in coolers panel joints. When this happens, Grocery operators will need to treat the damaged panel-joint condition, which is an added hit to the operation’s bottom line. The effects of physics are a constant challenge that is more difficult to overcome when working with traditional wood framing.

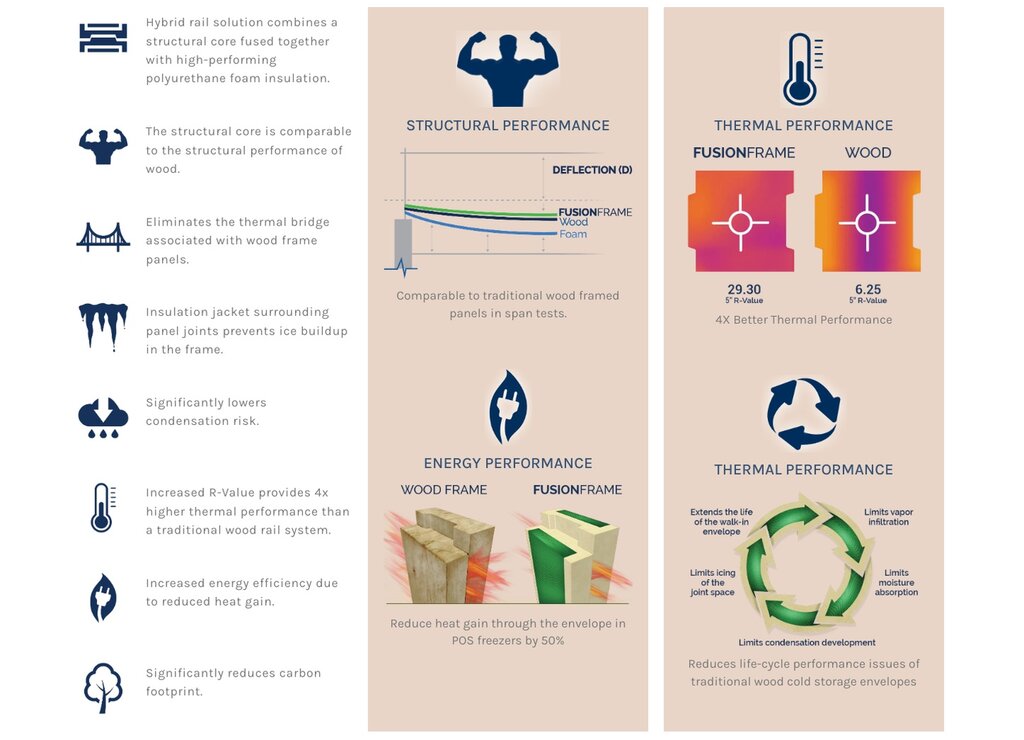

FUSIONFRAME is a proven innovation in the Grocery industry due to its design, which combines the structural performance of wood with the thermal performance of polyurethane insulation. The result? A framing system that increases walk-in unit R-Values to a level that slows the rate of heat flow and condensation formation, while limiting issues concerning life-cycle performance that can plague traditional plain wood-framed systems.

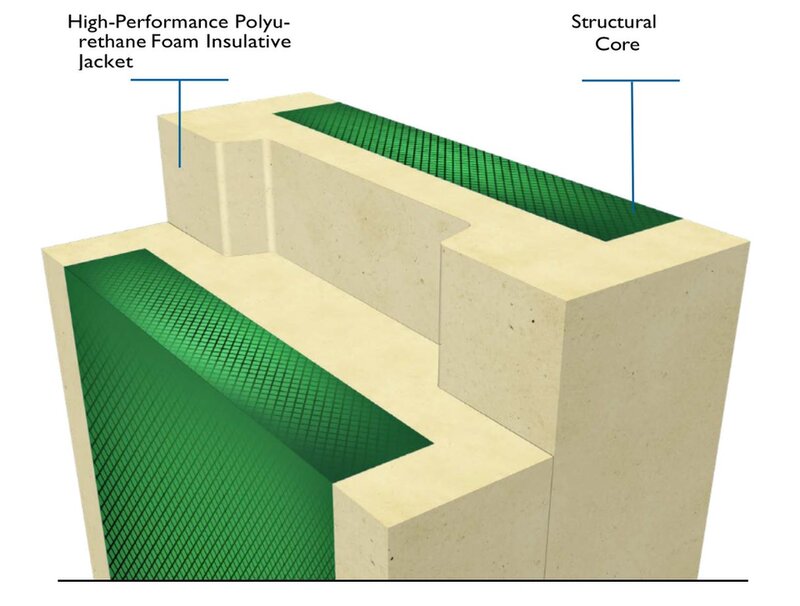

The key to the improved performance of the FUSIONFRAME system is a method of construction that injects a polyurethane foam insulation jacket around the structural member. The polyurethane is injected with a blowing agent that forms a rigid insulation - but only 3% of the insulation is a solid. The other 97% consists of millions of miniscule air bubbles which contain the blowing-agent gas inside them. These gas-filled bubbles are better able to resist the flow of heat through them when compared to wood.

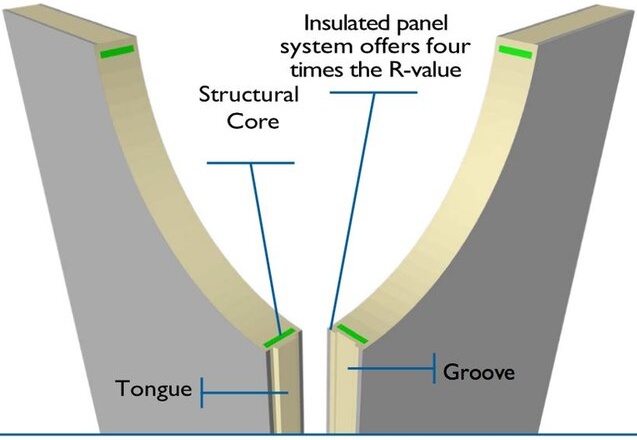

Wood framing is up to 15 times denser than the polyurethane foam, and the principle of thermodynamics tells us that heat can flow more readily through denser materials. The result is that using polyurethane foam gives the FUSIONFRAME an R-Value of R5.9 per inch of thickness, while the typical R-Value of wood is R1.2 per inch of thickness, making the FUSIONFRAME system around 4 times more resistant to heat flow than wood.

Keeping in mind the ability of the FUSIONFRAME to better resist heat flow and condensation formation, there are two main benefits for Grocery operators who choose to install walk-in coolers and freezers that feature the FUSIONFRAME technology:

- Energy Savings. A high volume of heat that flows into the walk-in unit will force the refrigeration system to work harder to remove it, along with any humidity that is present. If less heat is flowing into the unit, there is less to be removed by refrigeration system. This requires less electricity to power the system, which lowers utility costs.

- A More Airtight Construction.FUSIONFRAME rails use a foam tongue-and-groove connection that fits together more securely at the joints than wood. This allows the frame components to essentially seal themselves through a locking action that restricts moisture vapor from entering the center of the panel joint. This reduces the chance that any vapor will get deep enough into the panel joint to create condensation and build ice on the framing, which can shorten the walk-in’s life cycle and result in costly repairs or the need for premature replacement.

Heat is constantly trying to fight its way into the walk-in unit through the thermal envelope – walls, ceilings, floors, doors and windows. Operators in the grocery, foodservice, convenience store, big box retail, restaurant, warehousing and scientific industries have been battling this problem since they first deployed walk-in coolers and freezers.

There are nine significant reasons why the FUSIONFRAME system is a step forward in the performance of walk-in unit frame and rail operation:

FUSIONFRAME® from KPS Global, Inc., is a revolutionary frame/rail system that combines a structural core comparable to wood and polyurethane foam in a method of construction that can be five times more efficient than traditional wood frames in keeping unwanted heat and humidity from entering walk-in storage units.

- The structural core embedded in polyurethane-foam insulation allows less heat transfer than traditional wood-framed rails, resulting in lower refrigeration run time and electricity cost.

- The significantly lower rate of energy flow eliminates the problems that can be caused by humidity and its resultant condensation

- The FUSIONFRAME R-Value does not degrade over time like wood

- Reduces the potential for ice to form in the freezer frame like wood

- The softer foam rail allows for a tighter, more heat-resistant fit at the joints

- Comparable to traditional wood-framed panels in span tests

- Contributes to a longer operational life cycle for the walk-in cold-storage unit

- Carbon footprint is reduced through a reduction in the amount of fossil fuels that are consumed during the operation of the refrigeration system. Further, the polyurethane foam used in the FUSIONFRAME has zero global warming potential.

- Due to FUSIONFRAME thermal properties, it is less prone to thermal failures of the envelope. FUSIONFRAME was first installed in 2019 and has made no measurable changes in 5 years, which is a true innovation to maintaining the integrity of a walk-in.

Conclusion

The FUSIONFRAME system from KPS Global is a game-changer in walk-in cold-storage design and operations for grocery stores. It offers the best of both worlds: the structural benefits of wood combined with the insulative properties of foam. The benefits inherent in the design, construction and operation of the FUSIONFRAME system mean that Grocery operators who rely on walk-in coolers and freezers as a fulcrum of their businesses will not have to sacrifice performance over cost ever again.